Proseso ng Kemikal na mabigat na tungkulin Piston Methane Compressor

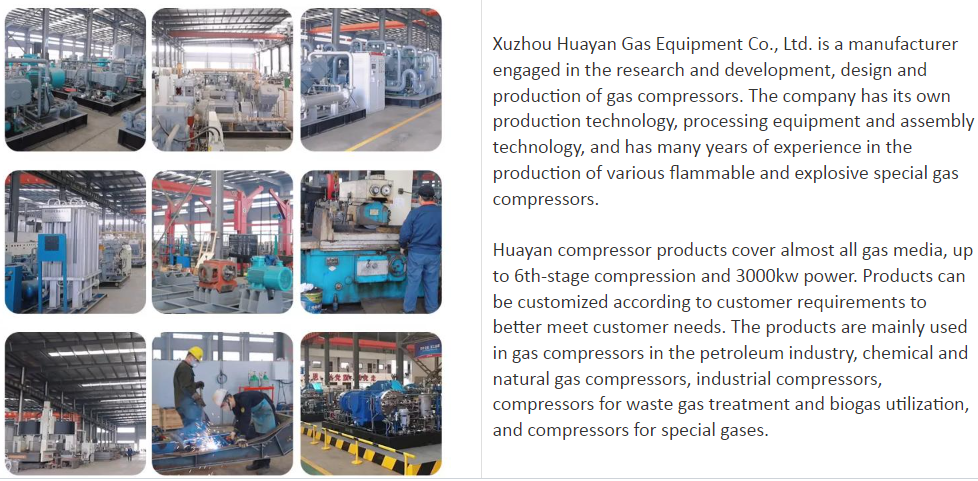

CHEMIACAL PROCESS COMPRESSOR-REFERENCE PICTURE

Piston compressoray isang uri ng piston reciprocating motion upang makagawa ng gas pressure at gas delivery compressor na pangunahing binubuo ng working chamber, transmission parts, body at auxiliary parts. Ang working chamber ay direktang ginagamit upang i-compress ang gas, ang piston ay hinihimok ng piston rod sa cylinder para sa reciprocating motion, ang volume ng working chamber sa magkabilang panig ng piston ay nagbabago naman, ang volume ay bumababa sa isang bahagi ng gas dahil sa pagtaas ng presyon sa pamamagitan ng valve discharge, ang volume ay tumataas sa isang gilid dahil sa pagbawas ng air pressure sa pamamagitan ng valve.

Mayroon kaming iba't ibang gas compressor, tulad ng Hydrogen compressor, Nitrogen compressor, Natrual gas compressor, Biogas compressor, Ammonia compressor, LPG compressor, CNG compressor, Mix gas compressor at iba pa.

Mga Bentahe ng Gas Compressor:

1. Mataas na kalidad ng materyal, Matatag at Maaasahang operasyon

2. Mababang gastos sa Pagpapanatili at Mababang ingay

3. Madaling i-install sa site at kumonekta sa pipeline system ng user para gumana

4. Awtomatikong pag-shutdown ng alarm sa pag-andar ng makina ng proteksyon

5. Mataas na presyon at daloy

Kasama sa lubrication ang:Oil lubrication at oil free lubrication;

Kasama sa paraan ng paglamig ang:Paglamig ng tubig at paglamig ng hangin.

Kasama sa uri ng pag-install ang:Nakatigil, Mobile at Skid Mounting.

Kasama sa uri: V-type, W-type,D-type,Z-type

CHEMIACAL PROCESS COMPRESSOR-PARAMETER TABLE

| KemikalProcessCompresorParameterTkaya | |||||||

|

| Mdoel | Daloy-rate (Nm3/h) | Intake Pressure(Mpa) | Presyon ng tambutso (Mpa) | Medium | Rotorkapangyarihan (kw) | Mga sukat L×W×H(mm) |

| 1 | DW-1.0/1.0 | 60 | Normal | 0.1 | Exhaust | 4 | 2200×1800×1100 |

| 2 | ZW-0.15/(12-20)-(20-28) | 120 | 1.2-2 | 2-2.8 | Acrylic | 5.5 | 1600×1100×1400 |

| 3 | ZW-0.15/6.5-25 | 55 | 0.65 | 2.5 | Nitrogen | 7.5 | 1600×1100×1400 |

| 4 | ZW-0.85/(1.5-2)-4 | 120 | 0.15-0.2 | 0.4 | Carbon dioxide | 7.5 | 1600×1100×1400 |

| 5 | ZW-0.8/4-9 | 210 | 0.4 | 0.9 | Mababang temperatura ng ethylene | 7.5 | 1600×1100×1400 |

| 6 | ZW-0.67/(3-4)-(8-10) | 150 | 0.3-0.4 | 0.8-1 | Oxygen | 11 | 1600×1100×1400 |

| 7 | ZW-0.8 /8-12 | 360 | 0.8 | 1.2 | Vinyl chloride | 11 | 1600×1100×1400 |

| 8 | ZW-0.8 /8-12 | 360 | 0.8 | 1.2 | Lsobutene | 11 | 1600×1100×1400 |

| 9 | ZW-2.0/0.5-(2-3) | 155 | 0.05 | 0.2-0.3 | Hydrogen chloride | 11 | 1600×1100×1400 |

| 10 | ZW-0.12/50-60 | 300 | 5 | 6 | Syngas | 11 | 1600×1100×1400 |

| 11 | ZW-1.5/7 | 75 | Normal | 0.7 | Coalgas | 11 | 1600×1100×1400 |

| 12 | ZW-1.0/0.2-20 | 60 | 0.02 | 2 | Dimethyl eter | 15 | 1500×1200×1400 |

| 13 | ZW-0.95/8-12 | 420 | 0.8 | 1.2 | Propane | 15 | 1500×1200×1400 |

| 14 | DW-2.0/7 | 100 | Normal | 0.7 | Sulfur dioxide | 15 | 2200×1900×1300 |

| 15 | ZW-2.84-2 | 150 | Normal | 0.2 | Carbon monoxide | 15 | 1600×1200×1500 |

| 16 | ZW-1.7 /7 | 90 | Normal | 0.7 | Basag na gas | 15 | 1600×1200×1500 |

| 17 | ZW-0.65/1.0-25 | 65 | 0.1 | 2.5 | Ethylene | 15 | 1600×1200×1500 |

| 18 | ZW-0.85/0.4-25 | 60 | 0.04 | 2.5 | Basag na gas | 15 | 1600×1200×1500 |

| 19 | VW-7.0/0.1-1.0 | 400 | 0.01 | 0.1 | Hexane/propylene | 18.5 | 1600×1200×1500 |

| 20 | DW-1.1/19-23 | 1100 | 1.9 | 2.3 | Mayaman na gas | 18.5 | 2300×1900×1300 |

| 21 | ZW-2.0/(1-2.5_)-5.5 | 270 | 0.1-0.25 | 0.55 | C3/C4 | 18.5 | 1700×1200×1600 |

| 22 | ZW- 2.1/0.15-15 | 120 | 0.015 | 1.5 | Hexafluoroethylene/Hexafluoropropylene | 22 | 1700×1200×1600 |

| 23 | ZW-6.7/2.5 | 340 | Normal | 0.25 | Lsobutane | 22 | 1700×1200×1600 |

| 24 | ZW-1.5/4 | 90 | Normal | 0.4 | Trifluoromethane | 22 | 1700×1200×1600 |

| 25 | ZW-1.5/10-16 | 840 | 1 | 1.6 | Butadiene | 22 | 1700×1200×1600 |

| 26 | ZW-8.9/(0.2-0.4)-1.0 | 600 | 0.02-0.04 | 0.1 | Coalgas | 22 | 1700×1200×1600 |

| 27 | DW-3.0/8 | 150 | Normal | 0.8 | Mashgas | 22 | 2800×2200×1600 |

| 28 | ZW-0.9/6-25 | 310 | 0.6 | 2.5 | Nitrogen | 30 | 1800×1300×1600 |

| 29 | ZW-0.88/10-20 | 500 | 1 | 2 | Coalgas | 30 | 1800×1300×1600 |

| 30 | ZW-1.1/1.0-31 | 100 | 0.1 | 3.1 | Hilaw na gas | 30 | 1800×1300×1600 |

| 31 | ZW-1.0/7-20 | 400 | 0.7 | 2 | Nitrogen | 30 | 1800×1300×1600 |

| 32 | DW-3.0/20 | 150 | Normal | 2 | Freon | 30 | 2800×2500×1400 |

| 33 | DW-3.0/1-8 | 300 | 0.1 | 0.8 | Methyl chloride | 30 | 2800×2200×1400 |

| 34 | DW-3.0/(0.2-1)-10 | 240 | 0.02-0.1 | 1 | Pakuluan ang Gas | 30 | 2800×2200×1400 |

| 35 | ZW-0.63/3-200 | 130 | 0.3 | 20 | Nitrogen | 37 | 3200×2300×1600 |

| 36 | DW-1.4/2-35 | 210 | 0.2 | 3.5 | Mixed gas | 37 | 2800×2200×1400 |

| 37 | ZW-8.1/(0.03-0.1)-2.5 | 450 | 0.003-0.01 | 0.25 | Coalgas | 37 | 2000×1600×1600 |

| 38 | ZW-1.85/19-25 | 2000 | 1.9 | 2.5 | Umiikot na gas | 37 | 2000×1600×1600 |

| 39 | DW-6.0/5 | 300 | Normal | 0.5 | Analytical gas | 37 | 2800×2200×1400 |

| 40 | ZW-2.0/(2-3)-(12-16) | 360 | 0.2-0.3 | 1.2-1.6 | Ethylene | 37 | 2000×1600×1200 |

| 41 | ZW-1.2/(5-6)-20 | 400 | 0.5-0.6 | 2 | Nitrogen | 37 | 2000×1600×1200 |

| 42 | VW-3.0/(1.0-2.6)-8.0 | 420 | 0.1-0.26 | 0.8 | Butadiene | 37 | 2200×1400×1500 |

| 43 | ZW-1.5/2-35 | 210 | 0.2 | 3.5 | Pinaghalong gas | 37 | 2000×1600×1600 |

| 44 | VW-0.21/(20-30)-250 | 270 | 2-3 | 25 | Methane | 45 | 3200×2000×1600 |

| 45 | VW-2.0/2-36 | 300 | 0.2 | 3.6 | Pinaghalong gas | 45 | 2200×1600×1500 |

| 46 | ZW-2.5 /(6-16)-24 | 1380 | 0.6-1.6 | 2.4 | Acrylic | 45 | 2200×1600×1500 |

| 47 | ZW-3.0/10-16 | 1680 | 1 | 1.6 | C4 | 45 | 2200×1600×1500 |

| 48 | ZW-0.46 /(5-10)-250 | 200 | 0.5-1.0 | 25 | Methane | 45 | 3100×2000×1475 |

| 49 | ZW-0.4/(10-23)-80 | 350 | 1-2.3 | 8 | Ethylene | 45 | 2200×1500×1500 |

| 50 | DW-2.9/14.2-20 | 2220 | 1.42 | 2 | Tuyong gas | 45 | 2600×2200×1400 |

| 51 | DW-2.4/(0.5-5)-20 | 340 | 0.05-0.5 | 2 | Chloromethane | 55 | 2600×2200×1400 |

| 52 | VW-0.84/5-(150-200) | 250 | 0.5 | 15-20 | Oxygen | 55 | 3100×2100×1750 |

| 53 | ZW-2.9/14.2-20 | 220 | 1.42 | 2 | Tuyong gas | 55 | 2100×1800×1700 |

| 54 | VW-7.0/1.5-5 | 800-1000 | 0.15 | 0.5 | Oxygen | 55 | 2200×1600×1600 |

| 55 | ZW-1.8/80-85 | 7200 | 8 | 8.5 | Helium | 75 | 2400×1800×1500 |

| 56 | VW-10/8 | 600 | Normal | 0.8 | Ethyl chloride | 75 | 2400×1800×1500 |

| 57 | VW-12.5/5 | 750 | Normal | 0.5 | Oxygen | 75 | 2400×1800×1500 |

| 58 | VW-7.0/(0-0.05)-18 | 450 | 0-0.005 | 1.8 | Trifluoroethane | 75 | 2400×1800×1500 |

| 59 | DW-6.8/(0.05-0.2)-(14-16) | 400 | 0.005-0.02 | 1.4-1.6 | Ethylene | 75 | 2400×1800×1500 |

| 60 | VW-6/22 | 350 | Normal | 2.2 | Mababang temperatura ng ethylene | 75 | 2400×1800×1500 |

| 61 | DW-3.45/3.5-28 | 800 | 0.35 | 2.8 | Pinaghalong gas | 90 | 2400×1800×1500 |

| 62 | VW-20.48/0.5-4 | 1600 | 0.05 | 0.4 | Hydrogen sulfide | 110 | 3400×2200×1300 |

| 63 | DW-19/4-6 | 4800 | 0.4 | 0.6 | Umiikot na gas | 110 | 3400×2200×1300 |

| 64 | VW-15/13 | 780 | Normal | 1.3 | Carbon monoxide | 132 | 2400×1800×1500 |

| 65 | 2VW/20/8 | 1020 | Normal | 0.8 | Coalgas | 132 | 4200×2200×1500 |

| 66 | DW-22.4/0.5-4 | 1600 | 0.05 | 0.4 | Hydrogen sulfide | 132 | 3400×2200×1300 |

| 67 | DW-19/(0.05-0.1)-6.5 | 1000 | 0.005-0.01 | 0.65 | Hilaw na gas | 132 | 3400×2200×1300 |

| 68 | DW-7.73/4-15 | 2000 | 0.4 | 1.5 | C4 | 132 | 3400×2200×1600 |

| 69 | VW-16/0.2-10 | 960 | 0.02 | 1 | Oxygen | 132 | 3400×2200×1300 |

| 70 | DW-21/ 0.1-6 | 1200 | 0.01 | 0.6 | Analytical gas | 132 | 4200×2200×1500 |

| 71 | VW-1.0/20-200 | 1080 | 2 | 20 | Carbon dioxide | 160 | 4000×2000×1800 |

| 72 | DW-3.0/3-250 | 500 | 0.3 | 25 | Methane | 160 | 4000×2000×1800 |

| 73 | VW-5.4/5-30 | 1650 | 0.5 | 3 | Oxygen | 160 | 4800×2200×1300 |

| 74 | DW-18/0.1-22 | 1020 | 0.01 | 2.2 | Carbon dioxide | 185 | 5200×3000×1900 |

| 75 | DW-10/1-30 | 1020 | 0.1 | 3 | Phosphorus pentafluoride | 185 | 5200×3000×1900 |

| 76 | VW-2.6/5-250 | 800 | 0.5 | 25 | Methane | 185 | 3600×2200×1500 |

| 77 | DW-67/1.5 | 3420 | Normal | 0.15 | Pinaghalong gas | 185 | 3600×2200×1500 |

| 78 | VW-2.1/10-250 | 1140 | 1 | 25 | Coalbed methane | 200 | 5500×3200×2000 |

| 79 | 2VW-18/0.2-25 | 1110 | 0.02 | 2.5 | Exhaust | 200 | 5500×3000×2000 |

| 80 | 2VW-33.4/8 | 1740 | Normal | 0.8 | Methyl chloride | 200 | 5500×3000×2000 |

| 81 | DW-42/(2-3)-(3.5-4.5) | 6500 | 0.2-0.3 | 0.35-0.45 | Vinyl chloride | 220 | 5500×3000×2000 |

| 82 | DW-25/18 | 1300 | Normal | 1.8 | Difluoro Methane | 220 | 5500×3000×2000 |

Isumite ang INQUIRY PARAMETER

Kung gusto mong bigyan ka namin ng detalyadong teknikal na disenyo at panipi, mangyaring ibigay ang mga sumusunod na teknikal na parameter, at tutugon kami sa iyong email o telepono sa loob ng 24 na oras.

1. Daloy: _____ Nm3 / oras

2. Inlet pressure: _____Bar(MPa)

3. Outlet pressure: _____Bar(MPa)

4. Gas medium: _____

We can customize a variety of compressors. Please send the above parameters to email: Mail@huayanmail.com